I have worked as a researcher for the Harvard Microrobotics Laboratory under Prof. Robert Wood since February 2024. I spent Summer 2024 pioneering fluidic circuitry and rigid components for self-folding complex origami-inspired structures. During the 2024-25 academic year, I redesigned my self-folding structures to integrate novel actuator architectures. Currently, I’ve been developing a bio-inspired microrobot designed for untethered jumping, stabilizing and gliding through the air, and controlled landing. As part of this work, I analyzed how springtail insects use water adhesion and built a prototype meniscus-climbing robot using shape-memory alloy actuation. To fabricate these designs, I adapted layered 2D micro-manufacturing methods from earlier actuator circuitry work, creating small-scale structures that could be tested and refined.

Publications:

E. Challita, R. Viveiros, J. El-Rayess, V.M. Ortega-Jimenez, R.J. Wood, “Snow fleas’ glandular landings and meniscus climbing,” In preparation

E. Langenbrunner, J. El-Rayess, and R.J. Wood, “Design study of low-profile fluidic actuators for folding structure,” Soft Matter, In preparation

E. Langenbrunner, J. El-Rayess, and R.J. Wood, “Coupled Tendon actuation by GRIPs,” In preparation

Microrobotics Research

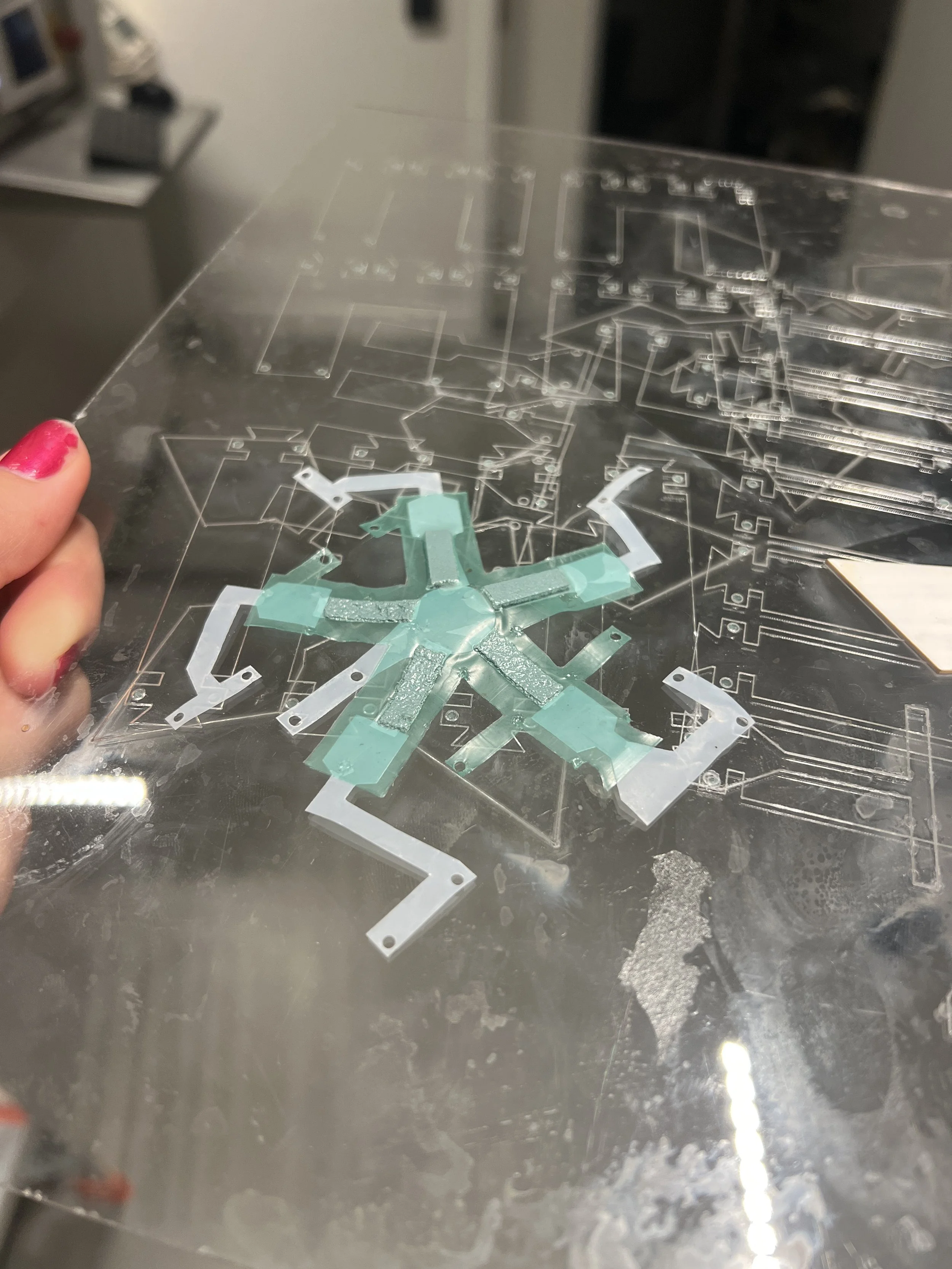

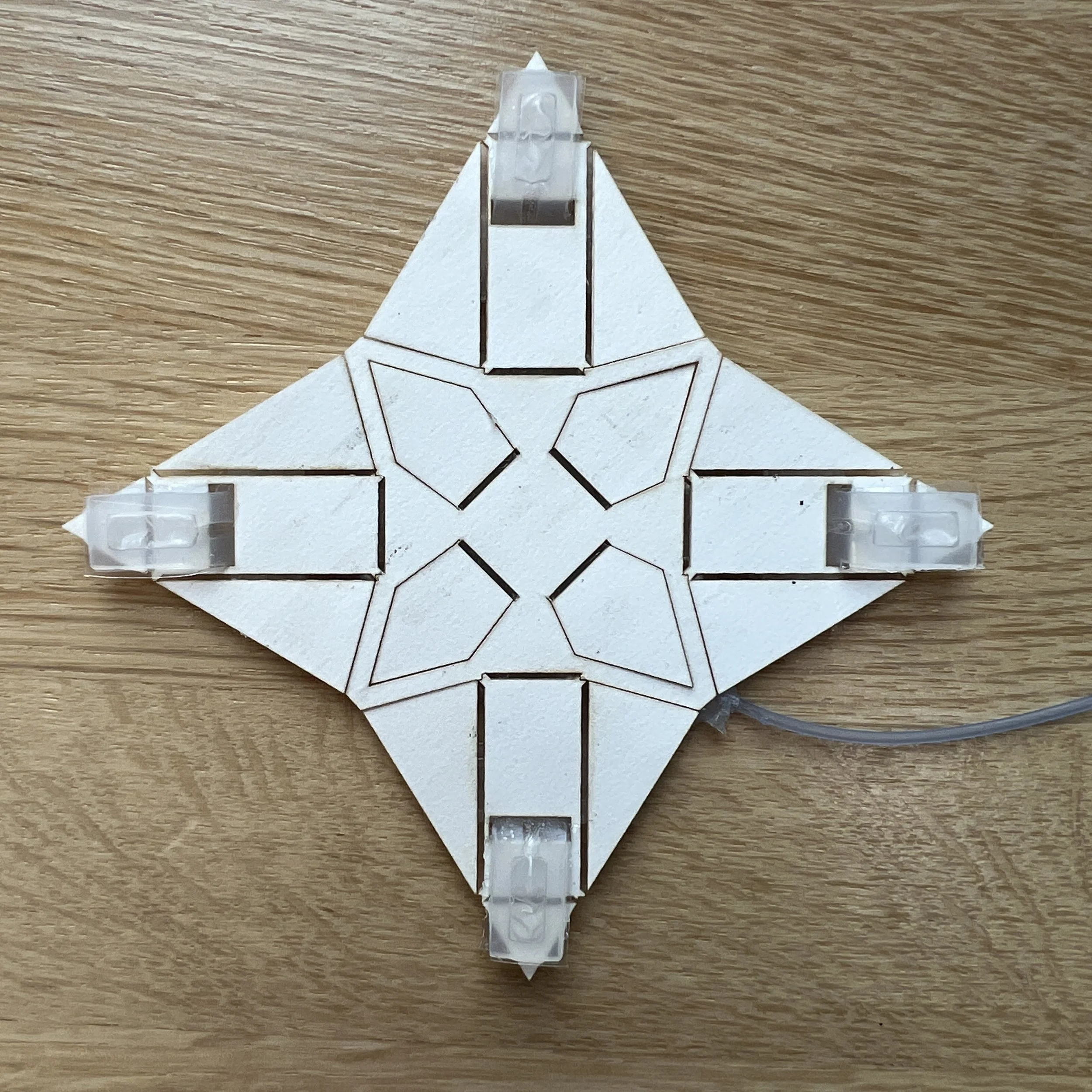

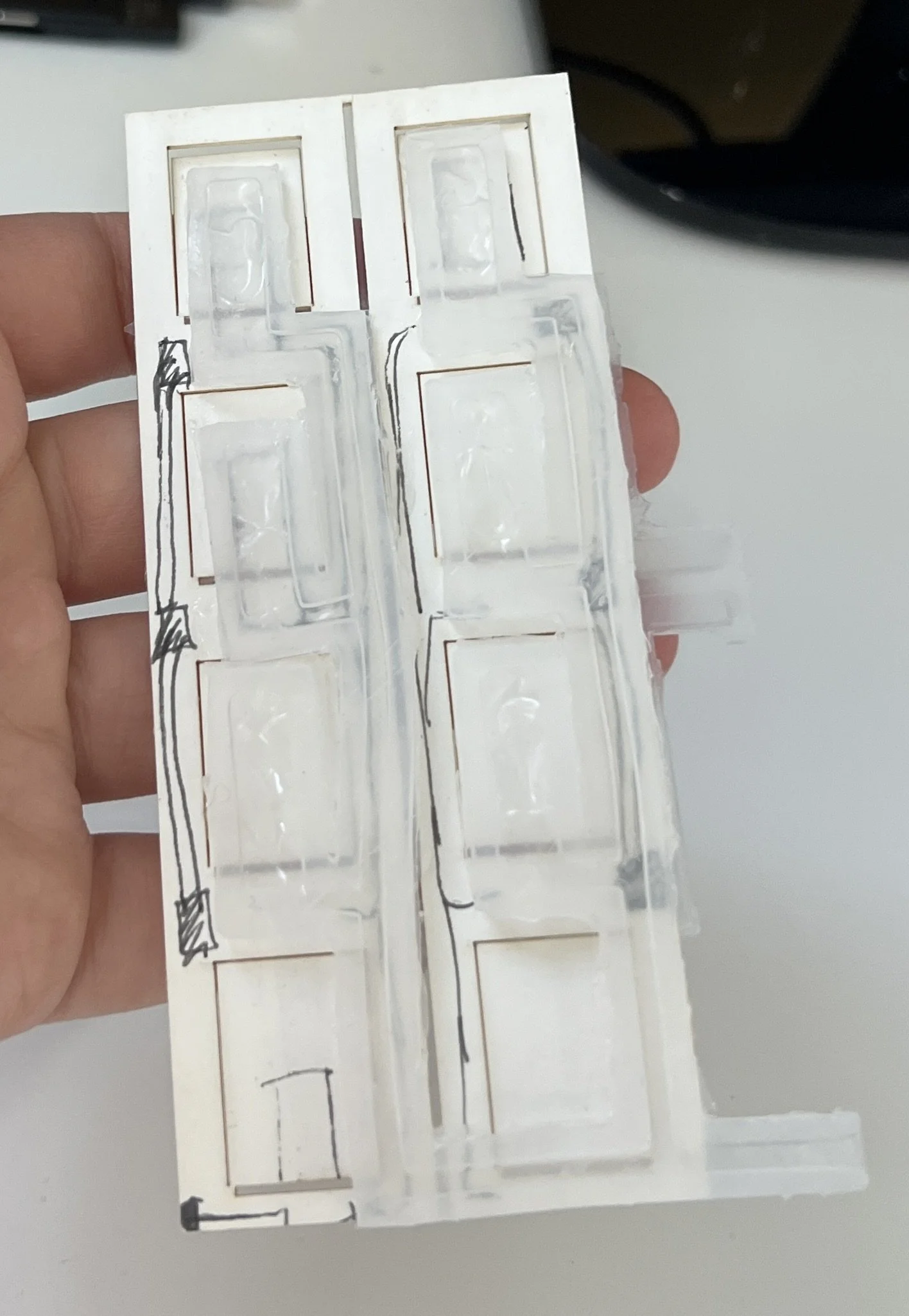

I redesigned the silicon fluidic actuator circuits using a layered TPU–adhesive–teflon–foam process, laser-cut and heat-pressed to form sealed channels, demonstrating adaptability across fabrication methods. I implemented novel actuator architectures, including stacked balloon actuators with tendon-driven motion, adapting the new circuitry for improved folding angle control.

Layered TPU–adhesive–teflon–foam Process

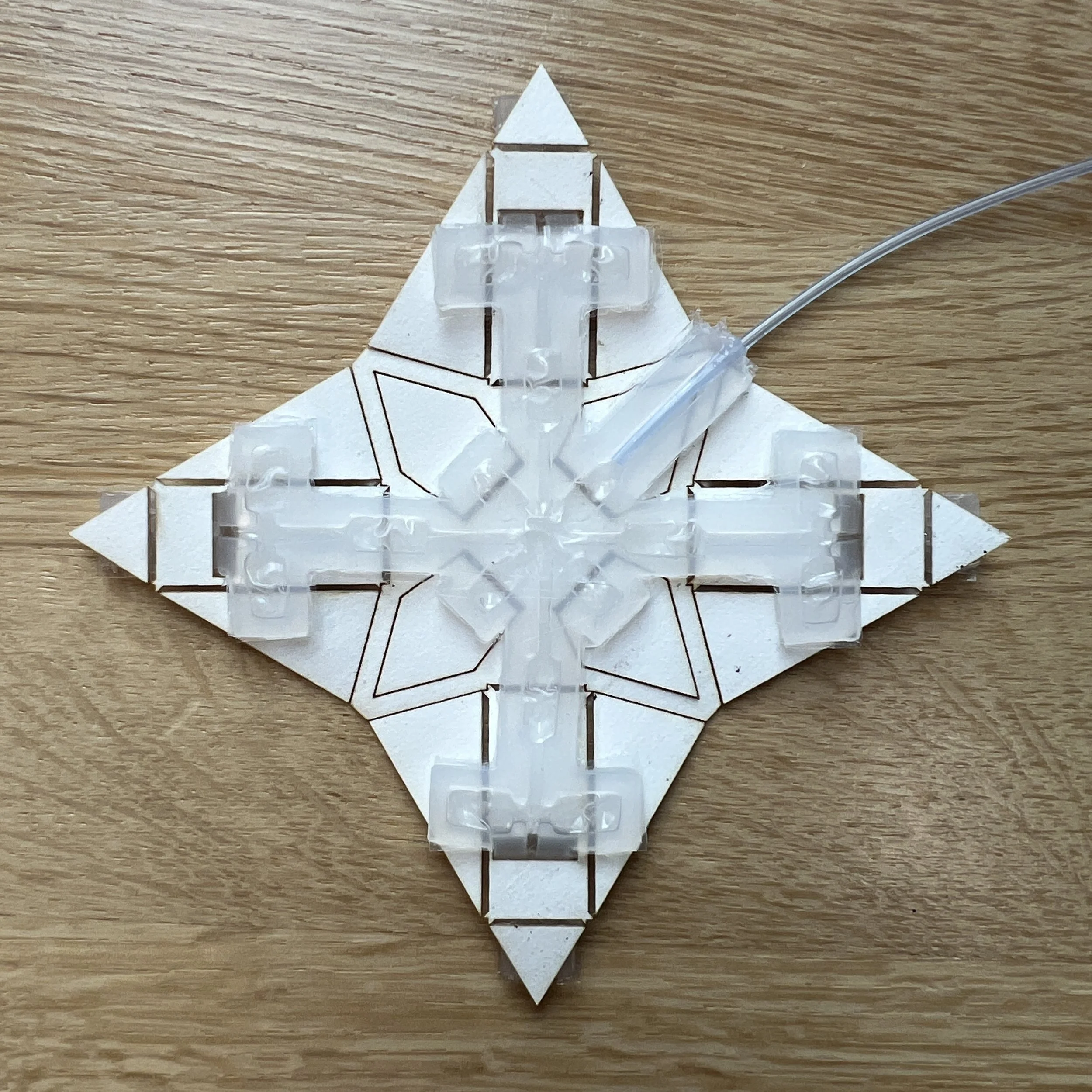

Redesigned Tulip Actuator Circuit

Redesigned Amaryllis Actuator Circuit

Integrated Tulip Actuator Circuit

Integrated Amaryllis Actuator Circuit (front & back sides)

The new actuators are made from TPU with pockets instead of silicon. In order design these actuators into circuits, I layered TPU, teflon tabs, foam, then another TPU piece. Each of the layers were laser cut, carefully assembled on top of one another, and placed precisely with the use of alignment holes. The whole assembly was then heat pressed; the teflon tabs were pulled out section by section so each pocket could be heat sealed; then the circuit was integrated into the foldable rigid component. The purpose of the teflon was to keep the TPU from melting together in the heat press where there needed to be pockets. Since the teflon tabs were meant to be pulled out so the edges of the TPU pockets could be heat sealed, they could only be designed so long without ripping. Thus, foam that maintained its structure after the heat press was used to keep plumbing channels open throughout the circuit of pockets instead of removable tabs.

Examples of Novel Actuator Architectures

Part of the circuitry redesign involved implementing novel actuator architectures, including stacked balloon actuators with tendon-driven motion. These new architectures allowed for improved folding-angle control. The videos above are examples of some of these novel actuators that accurately inflate to a specific angle.

September 2024 - May 2025

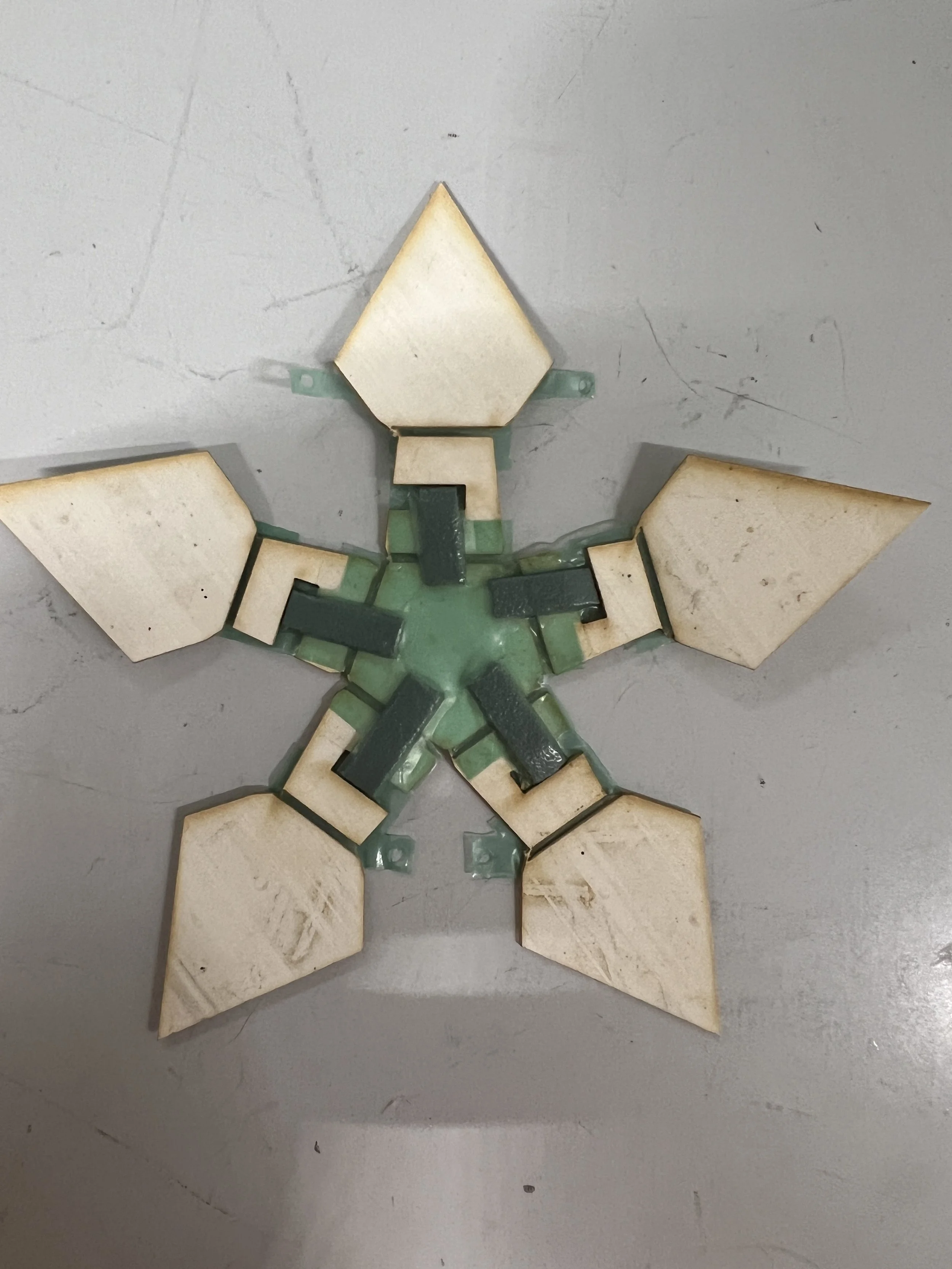

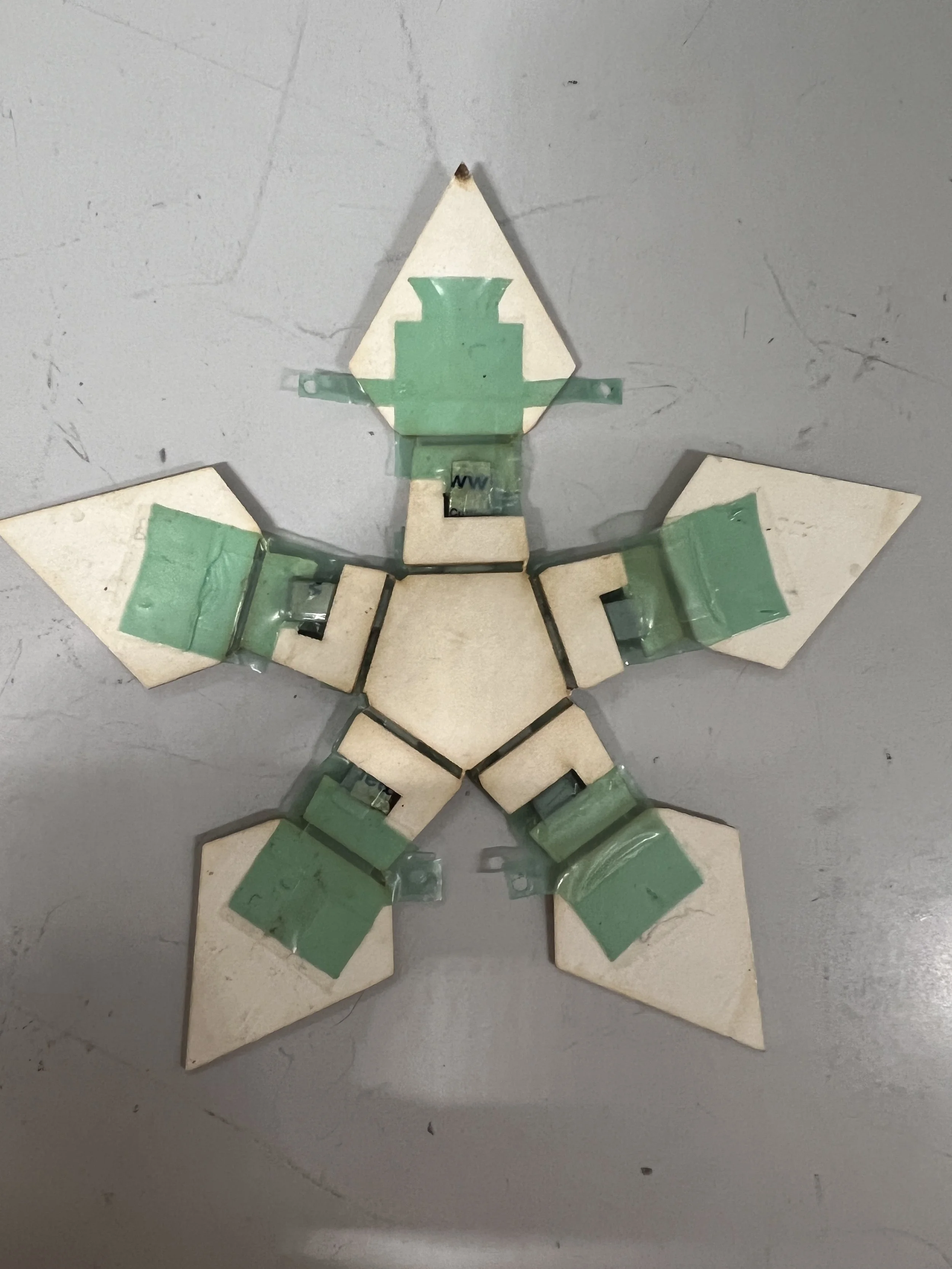

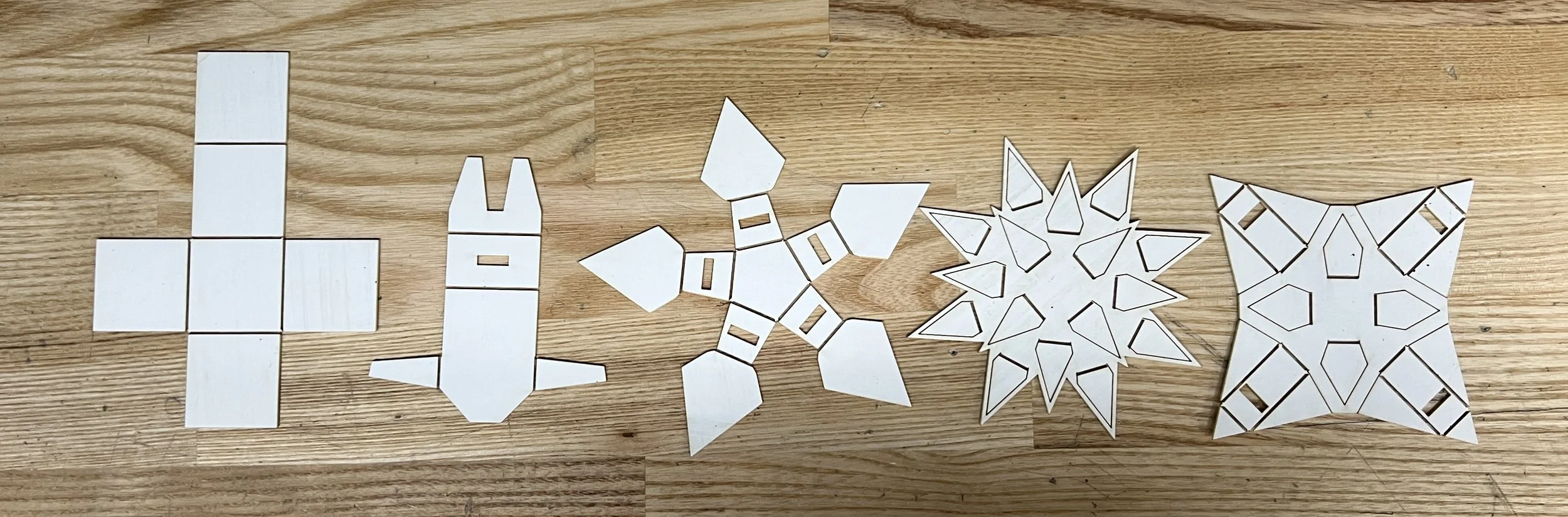

I developed fluidic circuitry and rigid components for self-folding complex origami-inspired structures. Namely, I developed a Frog (Video 1), Chrysanthemum (Video 2), Amaryllis (Video 3), and a Tulip (Video 4).

Video 3

Image 1

Image 4

Image 7

Video 2

Video 4

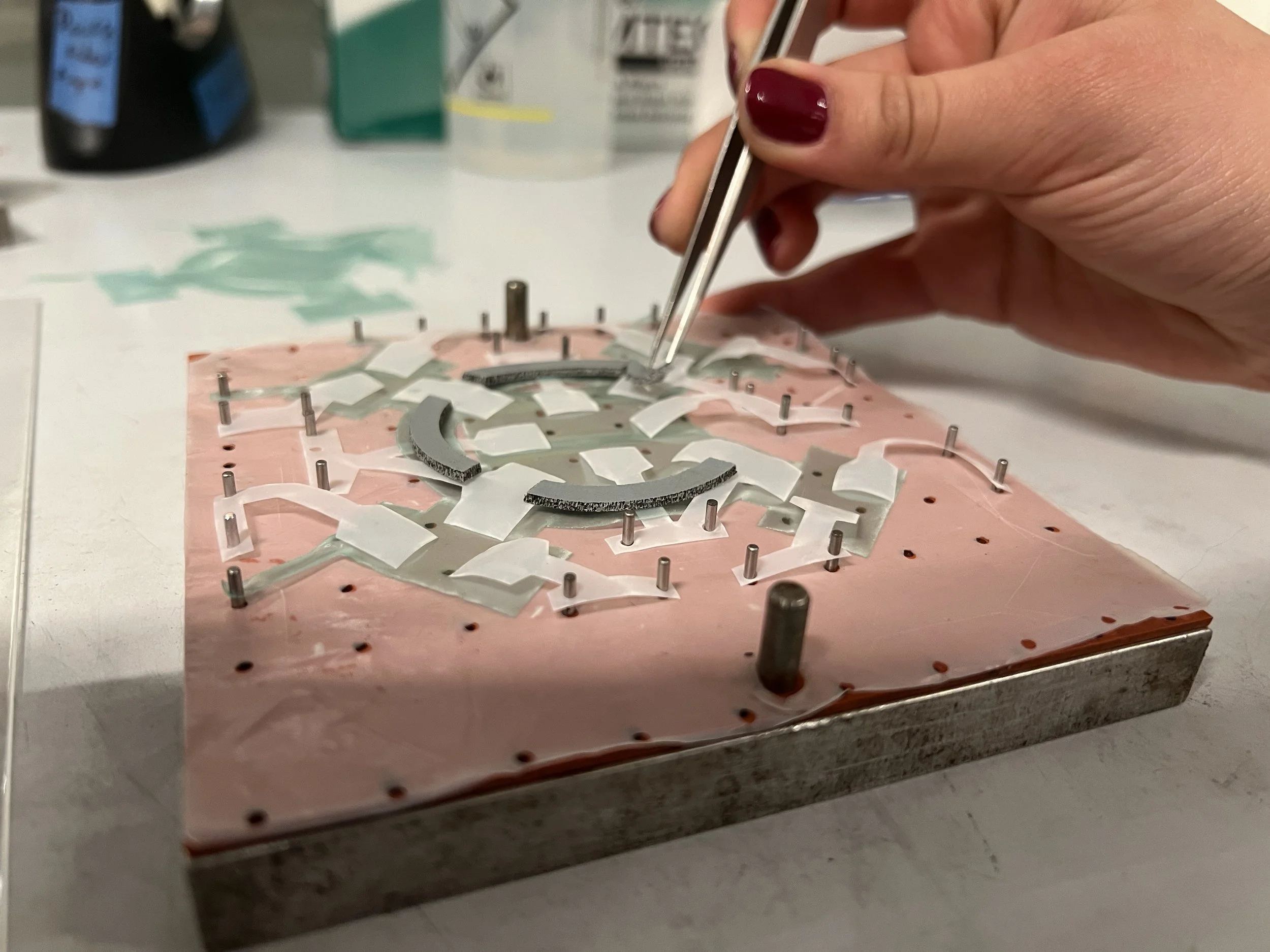

The actuator circuits were made using a silicon molding process and 3D printed molds created in SolidWorks. There is a top mold (Tulip example: Image 2) that fits into the bottom mold (Tulip example: Image 1) in order to create pockets in the silicon when it cures. This allows the circuits to have dual-sided actuation (Images 4 & 5) once they are integrated into the rigid components (Tulip example: Images 3 & 6). Throughout the circuit development process, I experimented with silicons of varying firmness (Soft: Image 4; Hard: Image 5), different aspect ratios, thicknesses, combinations of series and parallel circuits, etc. To manufacture the silicon circuits, I used the Spin Coater, Vacuum, and 3D Printer.

Image 2

Image 5

I used the silicon circuits to actuate the rigid components (Image 8) I made from applying a 2D heat bonding layered manufacturing process. The structures were layered (from top to bottom) with cardstock, wax adhesive, Polyethylene terephthalate (PET), wax adhesive, and then cardstock again. These layers allowed the rigid forms to maintain their structural integrity while being able to fold where the flexible PET was exposed, creating a hinge. After modeling the geometry of the layers in AutoCAD, I laser cut the wax adhesive and cardstock together and the PET separately. Next, I arranged the cuts on top of one another using a 3D printed guide with dowels (Image 7) and then heat bonded the layers. In order to formalize my process and results, I documented a knowledge base for each origami-inspired structure including bending angles, stiffness effects, dimensions, and common difficulties for future implementations.

Image 9

Image 10

Image 11

Image 3

Image 8

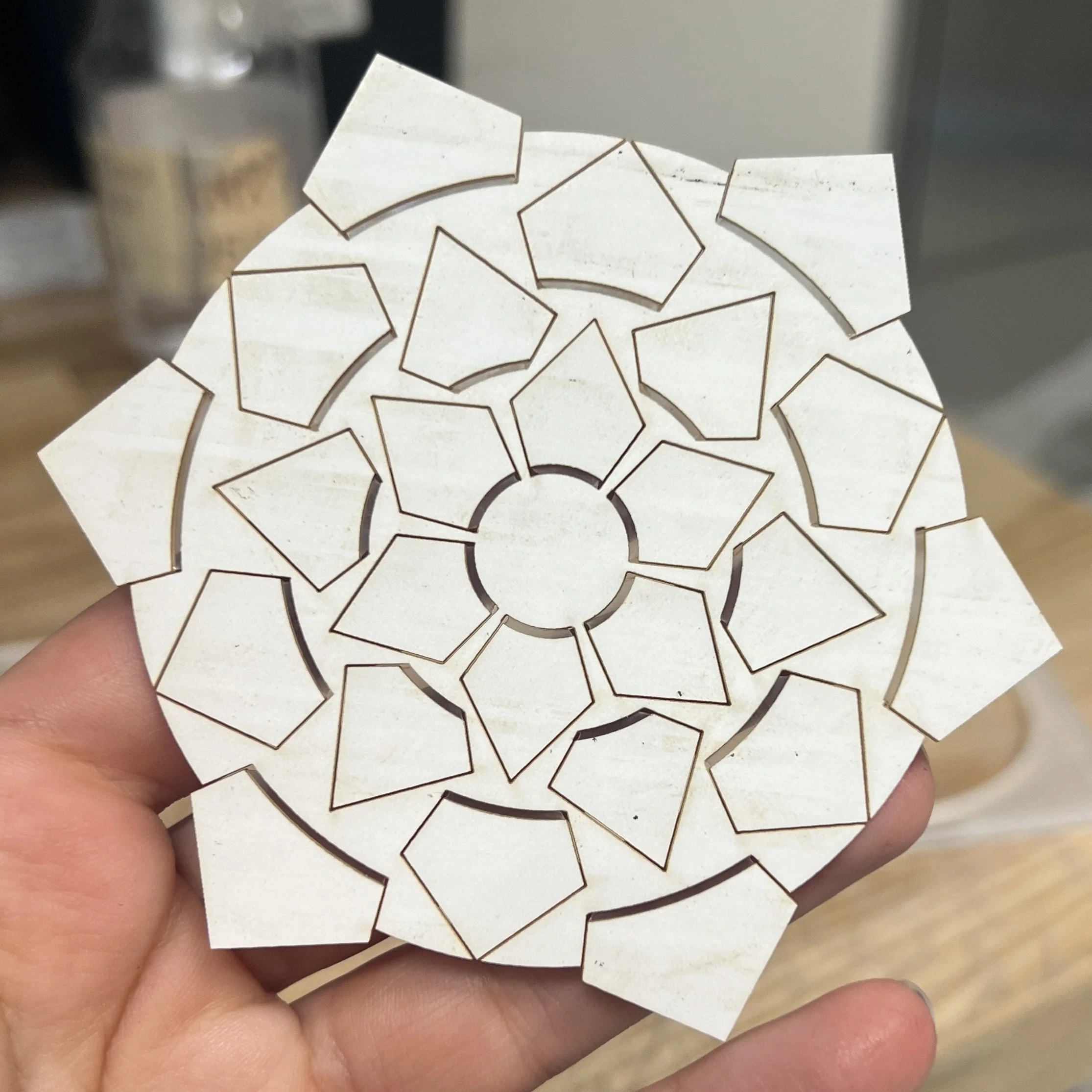

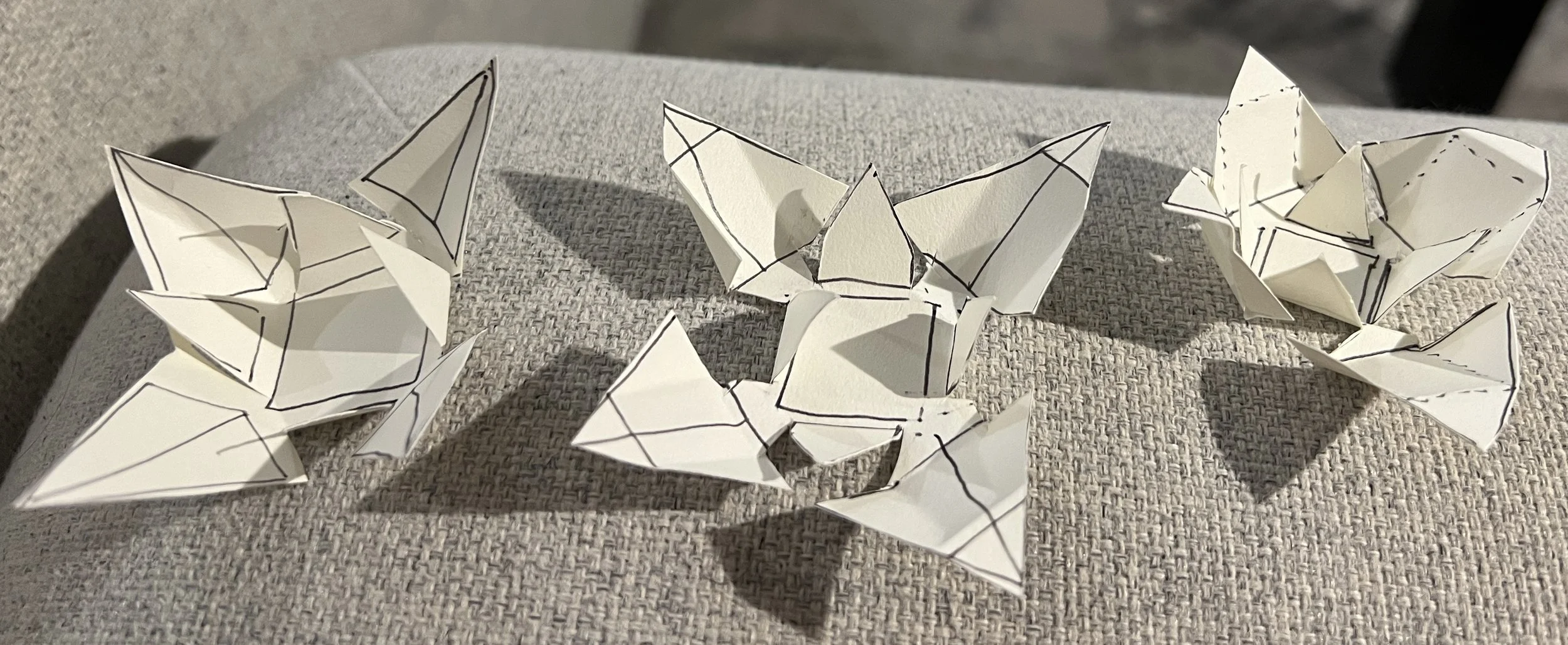

Aside from the physical research I conducted, the majority of the process involved rapidly prototyping various origami shapes and mapping out how they would actuate. For example, I would actually make the origami (Image 11) before trying to turn it into a singular folding piece. Next, I would make multiple paper prototypes of of the piece (Tulip example: Image 10). Finally, I would start realizing my designs with the process described above to determine whether they seemed viable. For example, one of my designs that didn’t pass the final testing stage was the Lavender-inspired structure (Image 12). Even if some designs didn’t work well when produced for the first time, like in the case of the original Chrysanthemum (Image 9), after iterating upon the design, they would turn out beautiful!

Image 6

Image 12

Video 1